Organo-Zeolite Oil Sorbent

The General Carbon Corporation’s Oil-Kleen is formulated to remove undissolved oil and grease from aqueous streams. A quaternary ammonia amine is impregnated onto natural zeolite, resulting in a granular product that attracts and holds free oil. The less soluble a compound is in water, the better GC Oil-Kleen will work. When used as a pretreatment for activated carbon, Oil-Kleen can greatly extend carbon life. There is no harmful increase in pressure drop as GC Oil-Kleen works. This keeps your system safe from over-pressurization problems.

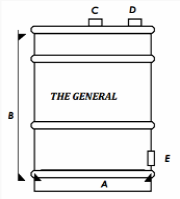

Oil-Kleen is supplied by the General Carbon Corporation in bulk or in 55, 85 and 110 gallon treatment units. These filters come complete with internal plumbing and are ready for installation. If larger flow rate systems are needed, please contact our office.

Filter Specifications |

55 Gallon | 85 Gallon | 110 Gallon |

| A – Diameter, Outside: | 24″ | 28″ | 32″ |

| B – Height, Outside: | 35″ | 39″ | 43″ |

| Inlet Fitting: | C – 1″ FPT | C – 1″ FPT | C – 1.5″ FPT |

| Outlet Fitting: | E – 1″ FPT | D – 1″ FPT | D – 1.5″ FPT |

| Drain Fitting: | E – 1″ FPT | E – 1″ FPT | E – 1″ FPT |

| Oil-Kleen Weight, lbs.: | 300 | 600 | 800 |

| Flow Rate, GPM (max): | 10 | 14 | 20 |

| Max. Pressure, PSIG: | 10 | 7 | 7 |

| Max. Design Temp., F: | 140 | 140 | 140 |

| Flow Direction | Downflow | Downflow | Downflow |

Media Specifications |

|

| Particle Type: | Granular |

| Mesh Size, (Standard): | 4×10 |

| Typical Density, lbs./ft.3: | 57 – 59 |

| g/cc: | 0.91 – 0.94 |

Installation & Startup – Fresh Oil-Kleen units must be prepared before they are used for the first time. A gentle backwash at 100-150% of the listed flow rate is required to clean product fines from the bed. This will insure that you have a minimum pressure drop through the unit. Multiple units can be connected in parallel to treat higher flow rates. Pressure gauges before and after the unit will allow you to determine pressure drop and the bed condition.

Maintenance – Once connected, Oil-Kleen units require little maintenance. The operating pressures should be monitored in order to help determine when the bed needs to be replaced. When the operating pressure reaches the maximum for the drum, bed material should be changed-out or the drum replaced with a fresh unit. The working life of each unit depends upon the type of contaminant in the water as well as its concentration and the liquid flow rate. A pressure relief device is advised to prevent damage to the canister in the event of excessive pressure buildup.

Recharging Oil-Kleen Filters – Once the oil capacity is used up, the unit should be removed and replaced with a fresh one. To purchase a replacement unit or arrange for a bed change-out, please contact our office.

Disposal – Dispose of spent Oil-Kleen in accordance with Local, State and Federal regulations. Because of the Anthracite coal in Oil-Kleen, the spent media has a high BTU value and may be disposed by use in fuel blending.

Click here for an MSDS Sheet of our GC Oil-Kleen: MSDS Oil Kleen 2013

CAUTION!

Wet activated carbon removes oxygen from air causing a severe hazard to workers inside carbon vessels. Confined space/low oxygen procedures should be put in place before any entry is made. Such procedures should comply with all applicable Local, State and Federal guidelines.