Leaders in

Activated Carbon

For 60 Years!

General Carbon Is A Leader In Activated Carbon

General Carbon Corporation, located in Paterson, NJ, has been in the activated carbon business for over 60 years. We offer a wide variety of activated carbon, adsorption equipment and wastewater remediation, purification, and other treatment services. Our friendly and knowledgeable team is available to assist in determining the appropriate solution for your needs.

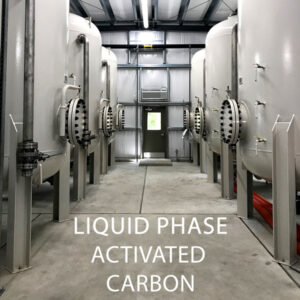

Activated Carbon Solutions

We maintain a large inventory of liquid phase activated carbon and vapor phase activated carbon products, which are available for immediate shipment. General Carbon Corporation can also design and build custom-engineered treatment systems, including complete pump and treat, SVE, and odor control systems.

Carbon Changeout Services

In addition, we offer on-site activated carbon changeout services throughout the United States. This includes the removal and regeneration of the spent carbon and its replacement with new media.

Adsorption Equipment

We offer a variety of adsorbers to accommodate a wide range of flow rates and applications. We also offer custom fabrication to meet specific site needs, such as higher flow rates and pressures.

Not sure what you need? Reach out to General Carbon directly for a free consultation with one of our activated carbon experts.

We look forward to hearing from you. Contact us by calling (973) 523-2223 during business hours, emailing us at sales@generalcarbon, or using the contact form below.